Products

Explore our full range of high-performance cable support and electrical solutions, engineered to meet global standards.

Our Products

Explore Our High-Performance Product Range

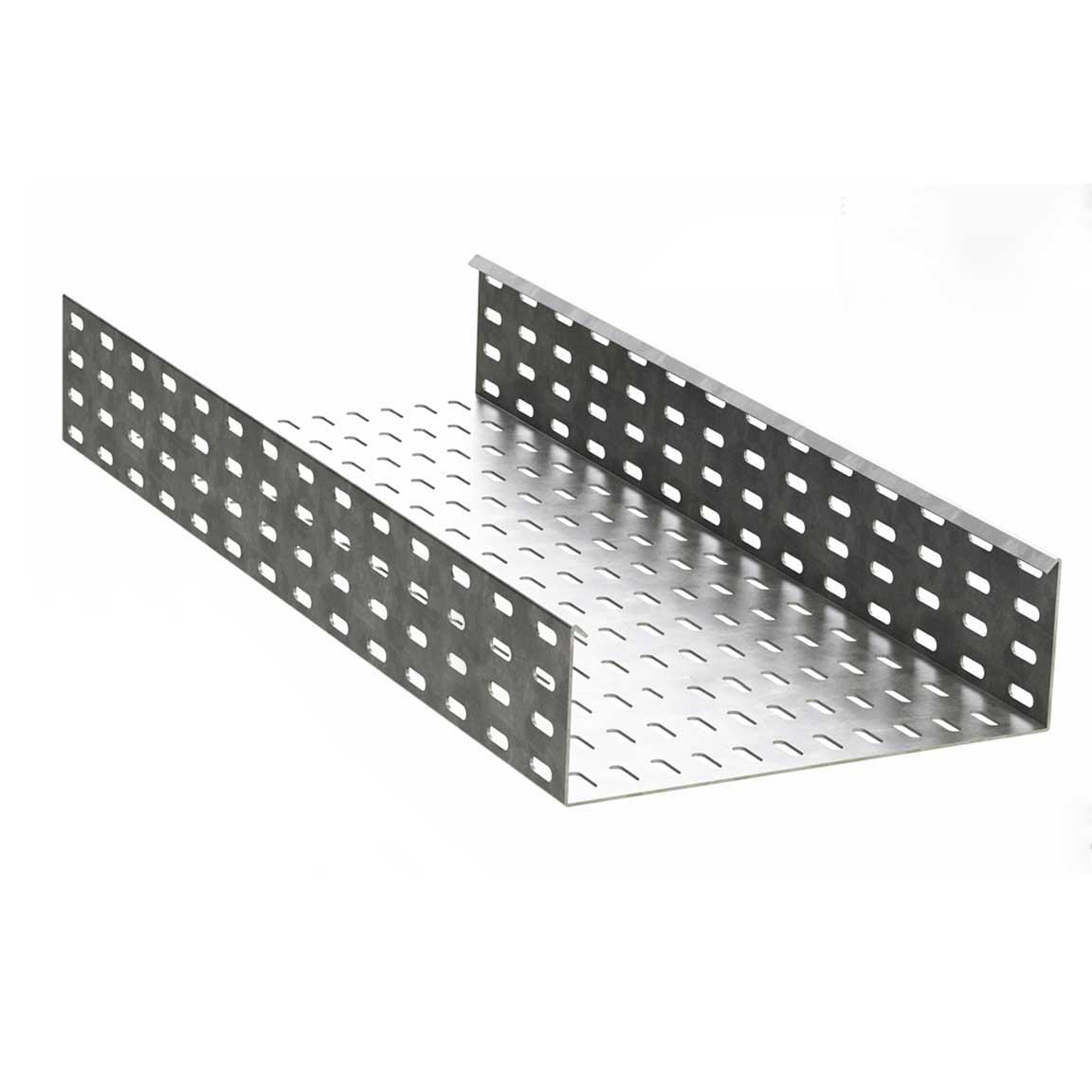

UTG cable trays are manufactured fully in accordance to british standard. standard lengths

UTG cable ladders are manufactured fully in accordance to british standard. standard lengths

UTG cable trunkings are also designed to ensure easy installation and are available in standard

UTG manufactures strut channels(both slotted & plain) as well as all kinds of support system

UTG cable basket tray design allows continuous airflow, prevents the buildup of dust, contaminants

UTG is the first and only manufacturer for gi switch boxes in the state of qatar. our production line can produce 50 boxes per minute.

Materials and Finishing Standards

| TYPE | FINISHING STANDARDS |

|---|---|

| PRE GALVANIZED (PG/GI) | Steel sheet conforming to BS EN 10327 & 10327 and BS EN 10142 & 10143 Standards. The substrate is mild steel grade where zinc coating is applied before metal forming with a coating thickness of 10–22 microns. |

| HOT DIP GALVANIZED (HDG) | Steel sheets of grades JIS G1312, JIS G3131 and RST37-2 DIN 17100-80 are used for fabricating, which are galvanized to the requirements of BS EN ISO 1461 & ASTM A123 generating a coating thickness of at least 65 microns. |

| STAINLESS STEEL (SS) | Sheet conforming to AISI Type 304 & 316 are used to fabricate Trays, Ladders, Trunkings and related accessories. |

| ALUMINUM (AL) | Sheet conforming to 1050 Alloy are used to fabricate Trays, Ladders, Trunkings and related accessories. |

| POWDER COATED (PC) | Trays, Ladders and Trunkings are fabricated and Powder Coated with RAL 7040 or RAL 7001 coating after Hot Dip Galvanizing as per requirement. |

Product Handling

Loading & Unloading:

Site deliveries should preferably only be made where suitable mechanical handling equipment is available on site. the delivered material must be treated with care. Lifting must only be carried out from the sides and the forklift truck tines must pass below a complete bundle. tines must never be inserted into the end of the bundle, unless provision is made such as special packing and/or extended tines, otherwise the safety limits of the lifting vehicle may be exceeded and damage may be caused to the equipment being lifted. for unloading by crane suitable lifting beams should be inserted from side to side beneath a bundle and these must be sufficiently long to avoid undue pressure on the edges of the bottom components.The tensioned banding used for securing bundles of equipment during transport is not suitable for lifting purposes. when cutting and bending appropriate eye protection must be worn to avoid injury. Sheared steel (particularly pre galvanized or stainless steel) does have relatively sharp edges and protective gloves must be worn during handling.

Storage Conditions:

Warehousing of product should be roofed and aired premises. Keep away from water. For protection of uncovered places damaged at assembly spray zinc paint is recommended. Wet storage stain (white rust) is caused by the entrapment of moisture between surface of closely packed and poorly ventilated material for an extened period. wet storage stain is usually superficial, having no affect on the properties of the metal. Light staining normally disappears with weathering. Medium to heavy build up should be removed in order to allow the formation of normal protective film. Proper handling and storage will help to assure stain-free material. if the product arrives wet, it should be unpacked and dried before storage. Dry material should be stored in a well ventilated low moisture “environment

to avoid condensation formation.

Looking for reliable cable management solutions or custom low-voltage panels for your next project? Advance Line Cable Management System L.L.C is ready to support you with certified products, expert engineering, and on-time delivery every time.

Why Choose Us

Built on Quality. Driven by Performance

UTG, we don’t just deliver products—we deliver confidence. Here’s why businesses across Qatar and beyond choose us as their preferred partner for cable management and low-voltage solutions

We are ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certified, with UL and QIL compliance—ensuring you receive products that meet international standards for safety, performance, and environmental responsibility.

From cable trays and ladders to low-voltage switchgear panels, we offer a full suite of solutions all under one roof. This reduces procurement complexity and ensures seamless system integration.

With in-house production and strong inventory, we fulfill urgent and bulk orders efficiently, keeping your project timelines on track.

Ready to Get Started?

Get a complete overview of our cable management systems, switchgear solutions, and technical specifications—all in one place.